In the sphere of raising watervarious technologies, such as centrifugal pumps and sump pump have been developed for years.

WaterThis is essential for drinking, cleaning and irrigation of our plants. We use pumps to pump water from many different sources such as, wells, exactly where we then utilize it for our wants. There a lot of different pumps available in the Water Lifting field and amongst those many types but ever since its inception, two among them has transformed hugely with water lifting technology that are Centrifugal pump and submersible pumps.

These cutting edge technologies are typical centrifugal pump technology and submersible pump, both of them function by moving water with spinning an impeller which generates a force that pushes the liquid outside. A centrifugal pump possesses an impeller composed of blades-which help to move water in the respective direction at high speed as it enters through a suction inlet. Water, by way of momentum and pressure then exits the pump casing at a higher velocity than that in which it entered.

Photo Credits: Crazzy EggBoth the centrifugal pump and submersible pumps have a lot to offer in terms of advantages, with many advancements since it is introduced. The installation, operation and maintenance of these pumps is very easy to do. Along with this, they feature an excellent flow rate that ensures operation is highly efficient and can shift big amounts of water. Secondly, these pumps are power-saving that require less consumption of the electricity as compared to other pump types which save costs and reduce environmental impact.

In addition, the centrifugal and submersible pumps are also a combination of these types along with innovations in other systems like variable speed drives for controlling pump's velocity even flow rate which allows adaptivity to various situations. Moreover, these pumps are furnished with self-suction features that assist in initiating the operation directly without any human effort. Especially beneficial in rural areas and remote locations, this option is available.

Read More: How to operate Centrifugal Pump and Submersible Pump The operating of centrifugal pumpSubmersible Operating Safety centrigufal pump.operating safety issues.authenticate victimisation means with concern treatments. First off, it is critical to choose the right pump for your exact application and then be sure you install it properly setting with the manufacturer recommnedations. Cleaning it when needed and inspecting the condition of your pump as often are two vital signs to let you know a clogged or debris buildup neglected with time.

In addition, when you start the centrifugal pump and submersible pump please fill enough water to priming the pump in order not a dry running. Dry running a pump causes friction between the impeller and casing which can cause damage to the pump, potentially leading it to catch on fire. Lastly, you should never touch the pump or any electrical connections while it is running since this can lead to electric shock and physical harm.

To turn on a centrifugal pump and submersible pump, it is important to choose brands with the most reliable performance in use. A good pump will be backed by a warranty that assures for material defects and workmanship during regular, predictable use. It also means selecting a suitable pump for your specific use and conditions. For example, if you are handling corrosive or abrasive fluid, then a pump with specific materials / coatings is required to resist chemical attacks or erosion. For instance, water pumped from a well or pond that is saline and contaminated requires the use of pump equipped with stainless steel pumps made to combat rusting and contamination.

ensure that product lasts long time make sure follow the idea of putting quality first. most important spare parts come from top centrifugal pump and submersible pump around the world. Make sure that price your products at cost that's affordable all customers. This will allow you make a profit.

products have been certified certification technical qualifications ISO 9001 being exported more than 70 countries, over 1000 buyers in Southeast Asia East Europe, America, Southeast Asia... products have achieved ISO 9001 technical qualification certification and centrifugal pump and submersible pump more than 70 countries more than 1000 buyers and regions in Southeast Asia, Eastern Europe America...

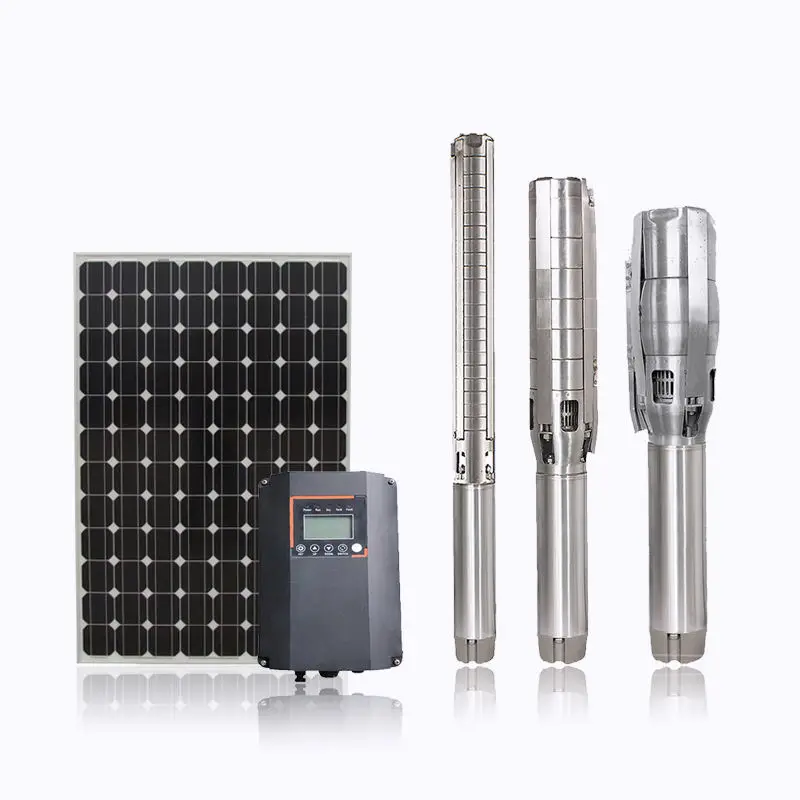

Solar well pumps surface pumps manufacturing design has been specialty 8 years. first manufacturer in China an incapsulated brushless DC motor with water cooling. First hybrid AC/DC solar pump manufacturer in China. most professional manufacturer in China that centrifugal pump and submersible pump deep ploughing and wedging the field of solar pumps the present.

company was established Taizhou city Jiangsu Province, with over 100 staffs at present. There eight series, around 400 centrifugal pump and submersible pump types of solar pumps that sold to more than 70 countries regions across world. We dedicated to offering customers services and products that are reliable, safe environmentally friendly, and cost-effective.

Copyright © Jiangsu Kangxiang New Energy Technology Co., Ltd. All Rights Reserved - Privacy Policy